May 2016. At SMAU our company was rewarded for developing our exclusive NEmoSY® system, designed and produced by DSC Nexus at an all-Italian supply chain. The awards didn't stop there.

|

|

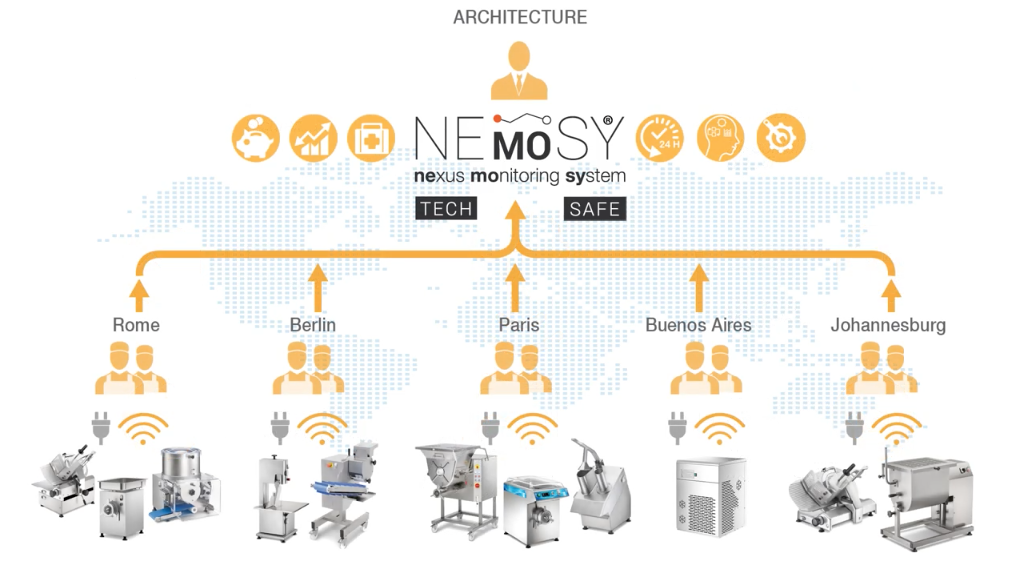

A technology that enables food processing machinery (not only ours...) to become SMART and interact with humans for total remote control of all machines used. This very briefly outlines what NEmoSY® does. It's an IoT system that collects useful information from the machine in real time and makes it easy to interpret and use by company management to optimise processes.

IoT pioneers? That depends. If by pioneers you mean explorers of unknown lands, then it doesn't describe Minerva Omega Group. But if you mean a spirit of initiative, research and an ability to interpret new requirements, it probably is the right term. NEmoSY® offers something tangible, usable and verifiable, and it has already been adopted by some in the sector.

NEmoSY® is a concrete global response to modern company requirements, a solution designed to connect humans and food processing machinery to increase work safety, prolong machine lifespans, maintain efficiency, and optimise running costs in general.

With NEmoSY® we are adding a probably unique value to our production because we are making our machines “smart” as well as world-renowned for their high technical and quality standards.

For further information on the NEmoSY® system:

https://www.minervaomegagroup.com/it/nemosy

https://www.minervaomegagroup.com/it/in-minerva-omega-il-futuro-e-gia-oggi

https://www.minervaomegagroup.com/it/-ph-metro-nemosy

https://www.youtube.com/watch?v=6SpGfgK97f8

In 75 Jahren Tätigkeit gelang es unseren Maschinen dank Fertigungsqualität und Sicherheit eine Führungsposition auf dem internationalen Markt einzunehmen. In diesem Bereich können Sie unsere Produktionsstätten auf einem virtuellen Rundgang durch die verschiedenen Abteilungen besuchen.

Nutzen Sie den Übersichtsplan, um unsere Organisation und Herstellungsmethoden aus Sicht von 4.0 zu entdecken Eintreten ››