Fast, noiseless, safe and reliable, compact easy to clean. These patty former models are the ideal equipment for butchers, super and hypermarkets, food processors, fast food, canteens and catering centers.

Fed with mince, they can automatically produce either patty or balls of the desired weight as it can be adjusted thanks to the forming cylinder. Various ingredients such as beef, chicken, fish can be processed in combination with grated bread, eggs, cheese, soy and spices. Even biscuits dough can be easily shaped. The pre-established weight of patties and balls is constant throughout the whole working cycle; very important issue for food processors, packaging plant and catering centers where product quantity per each portion must be as accurate as possible; one of the most valuable aspect.

Different shapes can be obtained just changing the forming cylinder: square, oval, customized according to customer needs.

RELIABLE »DIMENSIONS - TECHNICAL SPECIFICATIONS »

Optional » Certification »

The machine complies with CE standards in terms of hygiene and safety.

The machine complies with CE standards in terms of hygiene and safety. RELIABLE

Structure in stainless steel and anodized aluminium

Exchangeable cylinder made in Delrin®, one or two shapes

|

Interleaver |

|

Fast coupling paddle |

|

Wire cleaning with machine on |

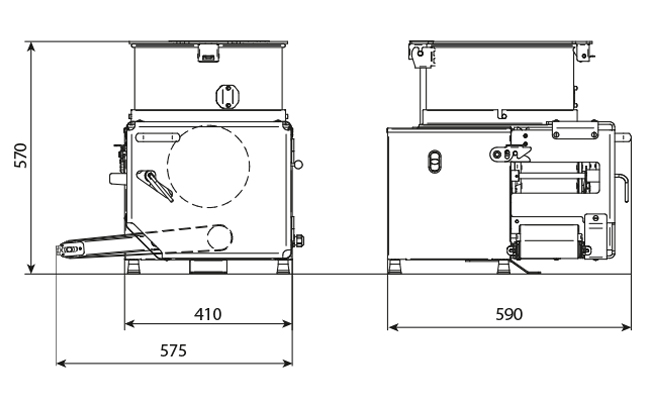

DIMENSIONS - TECHNICAL SPECIFICATIONS

| Feed pan capacity | l | 18 |

| Productivity | pcs/h | 1.000 |

| Threephase motor | kW (HP) | 0,3 (0,4) |

| Singlephase motor | kW (HP) | 0,3 (0,4) |

| Shape | ø mm |

Hamburger

Ø 50 a 125 mm

|

|

Cylindrical Meatball

2 x Ø 28 a 45 mm

|

||

| Net weight | kg | 48 |

FORMS

All the information shown in this document (descriptions, technical specifications, pictures, prices etc.) are indicative only, not binding and can be changed without notice. Despite it, this document remains valid.

Throughout our 75 years in business, our machines have earned themselves a high-profile spot on the international market for manufacturing quality and safety. In this section, you can take a virtual tour of the various departments at our production facility.

Use the plan view to discover our organisation and our production 4.0 Enter ››