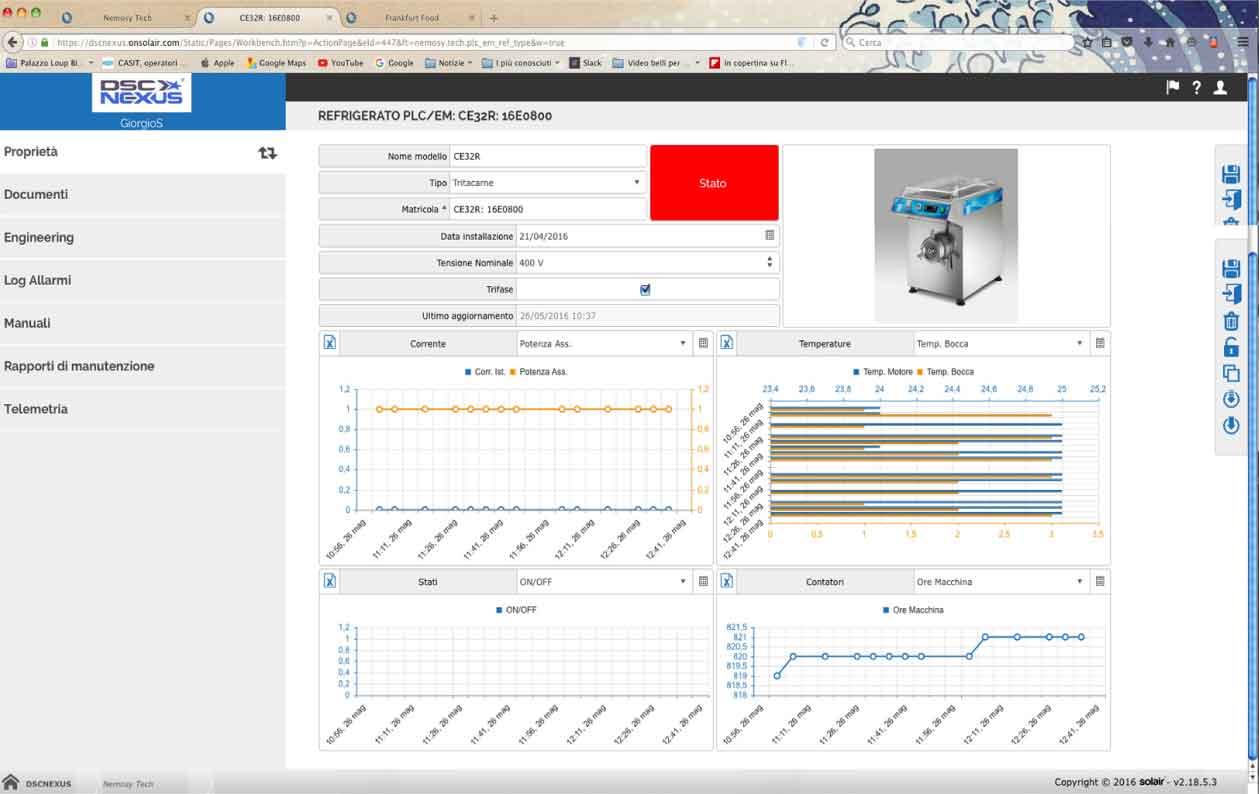

NEMOSY (NExus MOnitoring SYstem), a platform application solution that works by means of a network web connecting various pieces of machinery together, even of different types, so that they dialogue with a central control or with persons in charge of maintenance and safety.

Certification »

FEATURES

Interface (or electronic device) that can be connected to all types of three- or single-phase machine with industrial plugs (new or already installed)

Data transmission through a safe wireless system

Standard communication protocols and easy to install hardware

Cloud technology for storing captured data

Synchronisation with external systems (ERP, CRM, BI, AI, Control Room, others…)

Optional module for RFID CODE recognition

Compatibility with all types of machines used in the food processing industry (industrial and countertop mincers, vacuum packaging machines, bone saws, slicers, portioning machines, automatic hamburger forming machines, mixers, ice makers, rotisseries, ovens, washers, etc.)

Minerva Omega Group supplies its machines already set up for fitting the optional radio transmitter which, once installed, uses a gateway to send all the machine data and the data read by the on-board sensors to the cloud platform from where it can be accessed and shared with other management systems (ERP, CRM, Business Intelligence software):

open safety devices signals, alarms, working temperatures, absorbed current, operator ID, hours in use, hours worked, faults and machine downtimes, quantities and weights of processed products, management of maintenance cycles, technical reports, management of manuals and even more diagnostics …

On Minerva Omega Group machines that are already installed, and likewise for any other existing equipment (competitors, ovens, rotisseries, refrigerated counters and cabinets, packaging machines, etc.) a retrofit can easily be installed which is non-invasive and requires no specialised technical staff to fit it. The platform requires no specialist knowledge, no intervention on the IT system or knowledge of programming languages. The interface is intuitive and everything is parametric: from setting up users to the alert levels for each individual machine.

WHO IS NEMOSY INTENDED FOR

The application is designed for:

FUNCTIONS

Sending messages to the person in charge of maintenance, H&S Officer, email messages

Signalling non-conformities with the safety procedures set by the company policy or for unrecognised operators (identification by means of RFID CODE)

Saving digitally instruction manuals, lists of replacement parts, certifications, safety procedures, installation photos, maintenance operations, etc.

Periodic management of machine maintenance times and relative costs

Energy management of individual pieces of equipment/departments/supermarkets

Management of spare parts and relative costs

Fewer claims under warranty-10%

Fewer calls for technical assistance -10%

Fewer machine downtimes -20%

Product behaviour analysis 100%

All the information shown in this document (descriptions, technical specifications, pictures, prices etc.) are indicative only, not binding and can be changed without notice. Despite it, this document remains valid.

Throughout our 75 years in business, our machines have earned themselves a high-profile spot on the international market for manufacturing quality and safety. In this section, you can take a virtual tour of the various departments at our production facility.

Use the plan view to discover our organisation and our production 4.0 Enter ››