All versions of the automatic feed mincers in the C/E 900 range may be set up in line with the MPM 500 portioner to automatically process minced meat portions under perfect hygienic conditions, either in the “free flow” or “patty form” mode. The meat mincer+portioner is especially designed to improve productivity in hypermarkets, meat processing shops, etc.

RELIABLE » DIMENSIONS - TECHNICAL SPECIFICATIONS »

Optional » Certification » The machine complies with CE standards in terms of hygiene and safety.

The machine complies with CE standards in terms of hygiene and safety. RELIABLE

stainless steel casing and enclosure. All parts in contact with mincemeat in certified food-safe material

Heavy-duty, high-output. Variable speed

Maximum hygiene according to the HACCP method

Connecting kit according to specifi cations for quick and easy on the line connection of various brands of meat-grinders.

Adjustable outlet belt height for easy connection to downstream packaging systems

Portioning area with stainless steel cutting blade and paper roll. Photocell-adjustable portion length

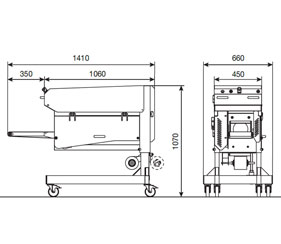

DIMENSIONS - TECHNICAL SPECIFICATIONS

| Head | 32/98 - 42/130 | |

| Meat-grinder head centre height | mm | 550 -750 |

| Portion outlet height | mm | 450 - 850 |

| Belt: variable speed | m/min | 6 - 30 medio 16 |

| Portions/min | n°/min | max 90 |

| Three-phase motor | kW (HP) | 0,45 (0,60) |

| Net weight | Kg | 131 |

PORTIONS

|

MPM 500+32/98 |

MPM 500+42/130 |

||

| (L) Width | mm |

105 mm |

125 mm |

| (P) Length | mm | 50 - 350 | |

| (H) Height | mm | 70 | |

| Weigh | kg | 0,2 - 1,5 | |

| Tolerance | % | +/-5% | |

Optional

All the information shown in this document (descriptions, technical specifications, pictures, prices etc.) are indicative only, not binding and can be changed without notice. Despite it, this document remains valid.

Throughout our 75 years in business, our machines have earned themselves a high-profile spot on the international market for manufacturing quality and safety. In this section, you can take a virtual tour of the various departments at our production facility.

Use the plan view to discover our organisation and our production 4.0 Enter ››